This article will give you a good idea about what is a hacksaw, how and when to use it, plus the right blades to use when cutting different metals or other materials.

Understanding the Hacksaw: A Versatile Cutting Tool

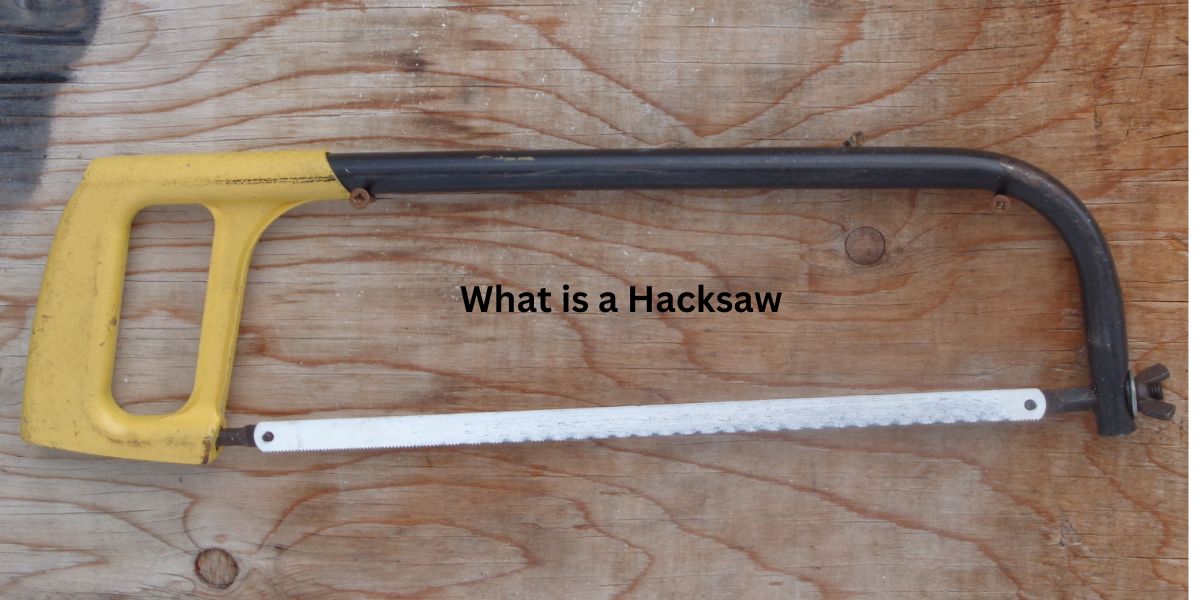

In the realm of hand tools, the hacksaw stands as a simple yet invaluable instrument designed for precision cutting of various materials. With its distinctive C-shaped frame and a fine-toothed blade, the hacksaw is a versatile device widely used in woodworking, metalworking, plumbing, and various DIY projects, and a must have for around the home projects.

Anatomy of a Hacksaw

The typical hacksaw comprises a frame with a handle at one end and a tensioning mechanism to hold a blade at the other, and with the frame being adjustable to accept 10 or 12 inch blades. The frame can be made of steel, aluminum, or other sturdy materials, providing a structure that maintains the blade under tension during use. The handle, often ergonomically designed, allows for a comfortable grip and precise control during cutting.

The blade of a hacksaw is a thin, long, and replaceable component with fine teeth, available in various tooth counts and materials suited for cutting different materials. High-tension hacksaw frames are also available, allowing for increased blade tension, which can be beneficial for more aggressive cuts or hard materials.

Applications of a Hacksaw

The hacksaw is a versatile cutting tool used across various industries and for multiple purposes:

- Metal Cutting: Among its primary applications, the hacksaw excels at cutting metal. Whether it’s pipes, rods, bolts, or more substantial metal components, the fine teeth of the blade allow for controlled and precise cutting, making it an ideal tool in metalworking and plumbing.

- Woodworking: While not as commonly associated with woodworking compared to other saws, the hacksaw finds a use in cutting smaller wooden pieces or intricate shapes, particularly in detailed or fine woodworking.

- Plastic and Composite Materials: The fine teeth and control offered by a hacksaw make it suitable for cutting through plastic, fiberglass, and composite materials. It’s often used in crafting, repairs, or model making.

Choosing the Right Blade

Selecting the appropriate blade for a hacksaw is crucial to ensure efficient and clean cuts. The choice of blade depends on the material being cut, and also the number of teeth on the blade, with 18 to 32 teeth per inch being suitable for most jobs, with the higher number the blade will make finer cuts.

- High-Tension Blades: Ideal for heavy-duty metal cutting, these blades withstand greater pressure and are used for cutting tough materials.

- Carbon Steel Blades: A versatile option suitable for cutting various materials like metal, wood, and plastics.

- Bi-metal Blades: Offering durability and flexibility, these blades are a composite of high-speed steel teeth and a flexible carbon steel body, designed for cutting hard and soft materials efficiently.

Tips for Effective Hacksaw Use

For optimal performance and safety, consider the following tips:

- Blade Tension: Ensure the blade is under proper tension in the frame to prevent bending or snapping during use.

- Cutting Speed: Maintain a consistent and moderate cutting speed for smoother and efficient cuts.

- Blade Orientation: Place the teeth of the blade facing forward for better cutting action. Some blades are directional and work optimally in one direction.

- Safety Measures: Always wear appropriate safety gear, including gloves and eye protection, to prevent injury from metal shards or splinters.

The hacksaw, with its simplicity and effectiveness, remains a staple tool in workshops, construction sites, and DIY enthusiasts’ toolboxes. Its versatility, ease of use, and affordability make it an essential cutting instrument in a wide array of applications, proving its timeless value in various industries and crafts. Around the home if an emergency plumbing fix arises you will certainly want to have a hacksaw on hand, so I wish you all the best on your home projects.