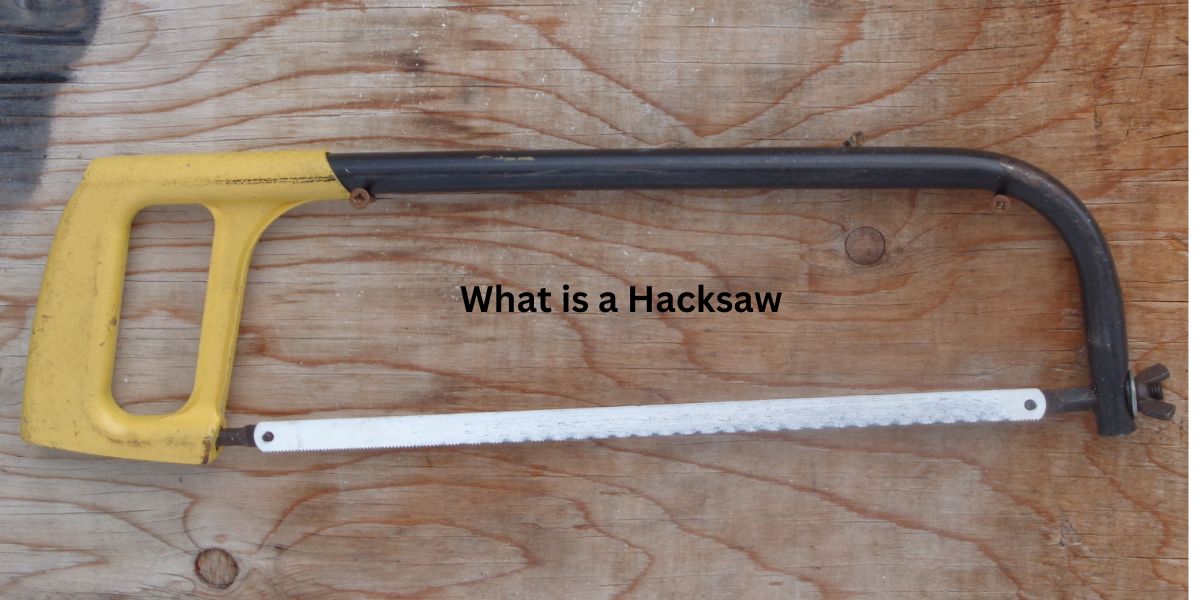

What Is A Hacksaw (What You Need To Know)

This article will give you a good idea about what is a hacksaw, how and when to use it, plus the right blades to use when cutting different metals or other materials. Understanding the Hacksaw: A Versatile Cutting Tool In the realm of hand tools, the hacksaw stands as a simple yet invaluable instrument designed … Read more